There are a few things that are always true in life. There will be more taxes than you want to pay. Your job will sometimes be awesome and sometimes will suck. You get what you pay for. Good power tools can be expensive. Protect your investment with timely maintenance. But how do you determine when it's time to maintain your power tools? What are some signs of wear you should be on the lookout for to help prevent further damage requiring additional repairs? Here's a quick overview to help get you started.

Check Manual

I know, this sounds way too simple, but your tool's manual will typically have any regularly needed maintenance listed, giving you a much better idea of what you should be undertaking in terms of maintenance and at what times. It will also often mention any specific issues that you should watch for while using your tools, allowing you to catch problem issues early and before they become much more expensive repairs down the road.

Keep Track of Recalls

You know that little postcard that often gets thrown out with all the extra packaging when you get a new power tool? It's actually pretty important in the long run. That registration card tells the manufacturer who owns its tools, so if there's a problem, such as a recall issue, they can contact you so that you can have service and repairs performed on your tool before it becomes a much larger problem.

Note Unusual Performance

Is it slowing down? Wandering more than usual? Though this can be an easy maintenance fix, such as sharpening a drill bit or changing out a saw blade, changes in performance can quickly turn into bigger problems if you try to power through just a few more boards, holes or cuts. Stop and make sure the tool isn't in need of repair before continuing.

Keep it Cool

We've all had it happen - a tool starts to give off that dreaded burned plastic smell. Stop. Right now. Though your tool will probably recover, if you continue using it to the point where it's burning up the motor, you'll lose overall functionality very quickly if you don't stop as soon as you pick up these scents or see smoke. Time to put down the impact drill and pick up an upgrade in terms of power instead of blowing what's left of the motor.

Treat Batteries Properly

Many issues start at the power source, and on cordless tools, that power source is the battery. Try to keep lithium ion batteries between 20-90% of capacity, because below and above these points is the range where the battery ages the fastest. Be sure to store your batteries cool, dry and protected in a case or box.

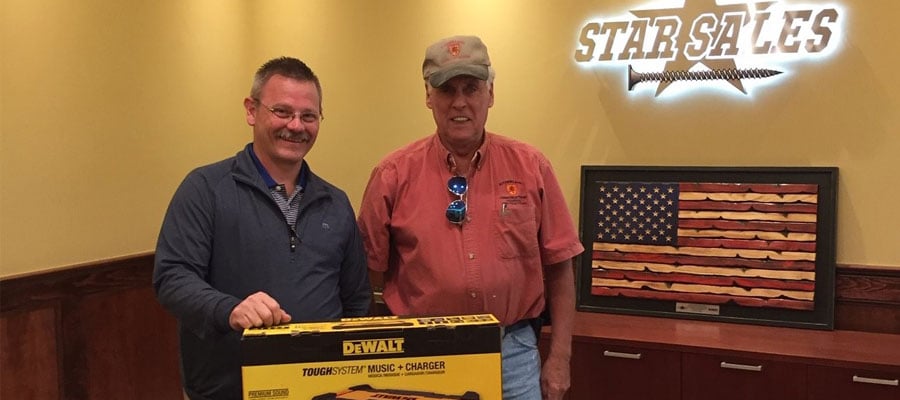

By taking the time to watch for signs of wear in your power tools and undertaking regular maintenance, you can gain a much longer expected useful lifespan from those tools. This both protects your investment and gives you a longer period of time before tools must be replaced. If you don't have time to take care of the maintenance and repairs needed for your tools, Star Sales can help. Our Power Tool Service Center in Woburn features highly-trained technicians who can make your tools rock again. Please feel free to contact us today to get started.